Blog

Laser Engraving News

DSS Plastics Group launches laser engraver solution.

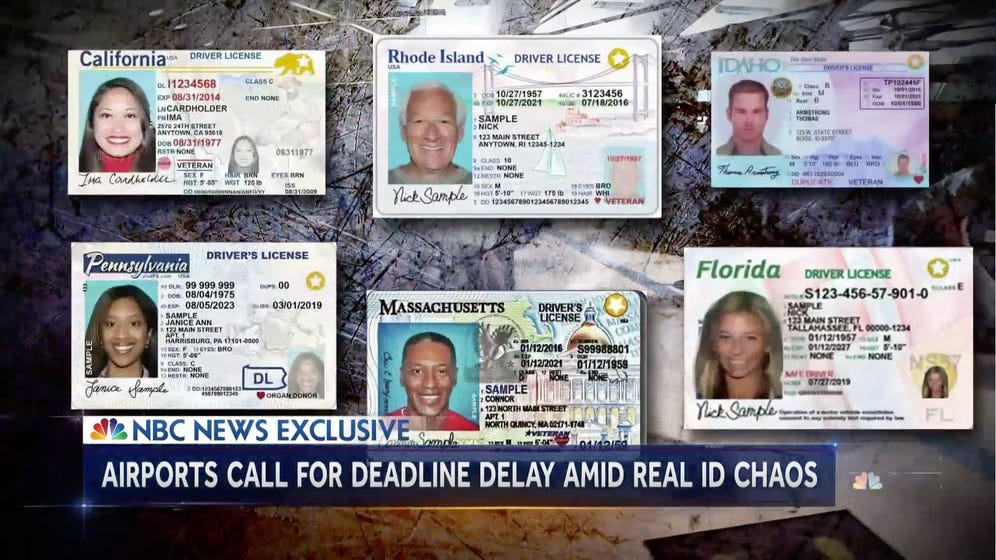

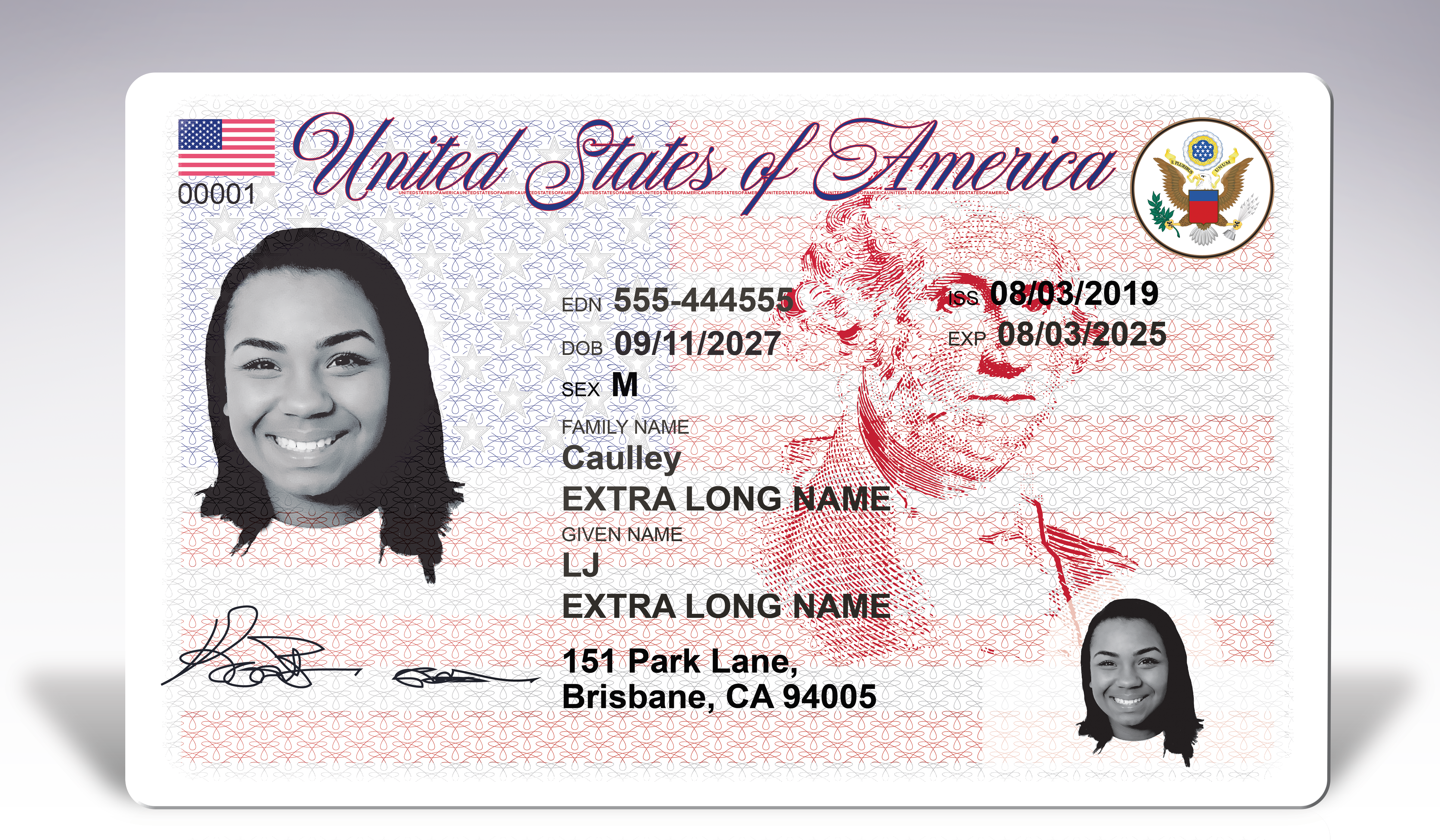

The ability to bring central issuance back into the identity sector is important. Issuing identity cards on site and on-demand eliminates long lead times and unnecessary costs/risks. Post 9-11, all driver licenses were produced at a card manufacturing plant. Not only the static images but also the variable data. The variable data was printed via a digital (variable) press and then sent through card production. The purpose of this was to ensure the variable data was sub-surface and built into the card body.

Let's take a look at the below history of the Wisconsin driver license. The top image was produced via dye-sublimation and 100% images on a desktop printer via ribbons. The 9-11 attack used counterfeit licenses printed in the same manner. After 9-11, states determined that this process was no longer secure and had 100% of the printing (static and variable) done at a secure card plant.

Moving forward and looking at the current Wisconsin DL, issuance is now being done by the states once again using laser engraving. The concept is rather simple, engraving is permanent. To alter an engraved card, one would destroy the card structure and defeat the purpose. Following Real ID and AMMVA card design guidelines, laser engraving is the new standards for variable data, card security.

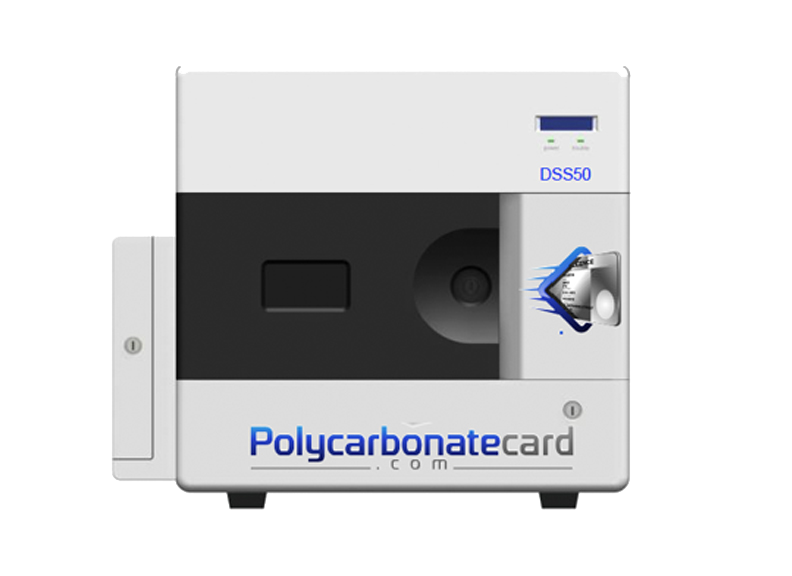

About the Polycarbonate Deluxe Engraver:

The PCD works best in a PC environment using either Windows 7, 8 or 10. The engraver is not Mac compatible. It is recommended to purchase a new PC for a clean install that will last for years to come.

High safety standard, IEC 60825-1 standard Class 1 laser product using a USB 2.0 interface to the PC. The PCD comes with key locks for the card stacker and output tray that meets most security audits.

Although industrial in performance, this machine fits on a desk for immediate issuance. The engraver weighs 150lbs and the dimensions are 22.5197" wide, 20.2756" long and has a height of 22.0472".

Card stacker allows for 350 cards, reject stacker 20 cards and the output stacker can hold 100 cards.

Normal card engraving takes roughly 50 seconds to complete and uses zero consumables. The laser life will handle roughly 50,000 cards before ending warranty.

Printing up to 1200dpi, the PCD will engrave clean and crisp images. For applications requiring dual sided engraving, such as MRZ printing on the card back, the engraver can be ordered with a card flipper.

Still need more info? Please contact us immediately.